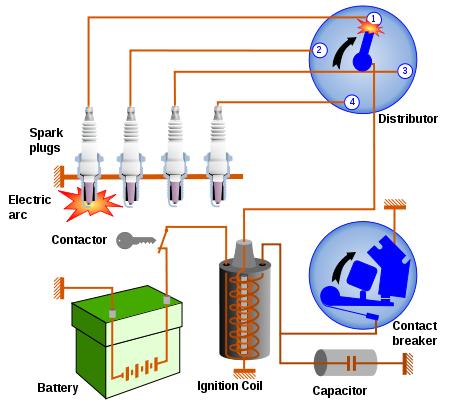

Fig 1

|

The

modern motor

vehicles are replete with advanced electrical and electronic

technologies. It

all started in 1902, when Robert Bosch introduced the double coil

magneto

system to the

internal combustion engines. These systems where too bulky to be used

in motor cars and in 1910, Delco introduced the

Battery Operated

Ignition system to Cadillac cars. The next development was

the Mechanical

Fig 2

|

Fig 1 |

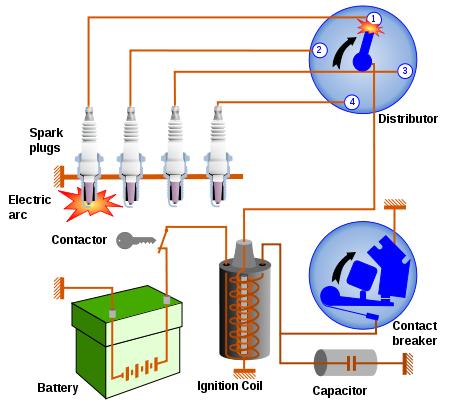

Motronic

(ECU), Sensors and Actuators Fig 3 |

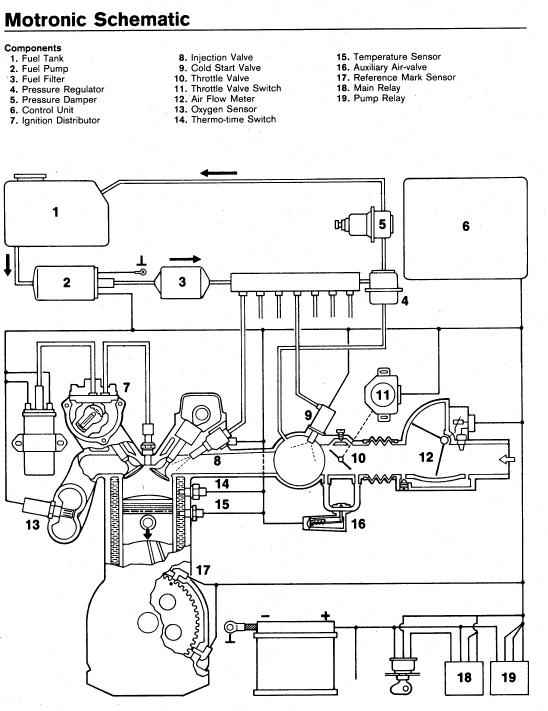

Areas Requiring Sophisticated Diagnostics and Analysis  |

|

The Present Challenges

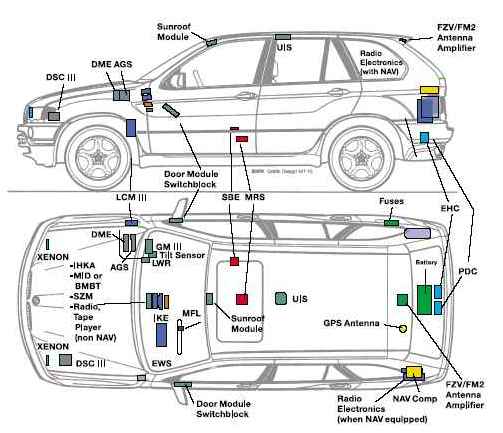

Nowadays, all motor vehicles have an ever growing number of on-board computers, which require sophisticated intercommunication systems (BUS). From Tyre Pressure sensors to drive-by-wire driver controls, everything in the modern car is controlled by computers. The later models have already replaced electrical wires with Fibre Optics and (FlexRay), to interconnect all ECMs (electronic control modules). This ever growing complex world of Digital and Analog Computerised Systems, although very reliable, require maintenance and repairs from time-to-time. The average car owner or auto electrician, can no longer perform the usual repairs. To be able to perform analysis, troubleshooting and repairs on these complex systems, the old faithful "tool box" has been replaced by computers running sophisticated software applications. Perfect examples of those complexities are the 2006 BMW X5 (Fig 4), the first production car to use FlexRay and (Fig 5), which shows the new FlexRay car network, soon to become a standard. Formula 1 drive-by-wire Systems |

BMW X5 Electronic Controlled

Systems Fig 4

Fig 5

|

| back |